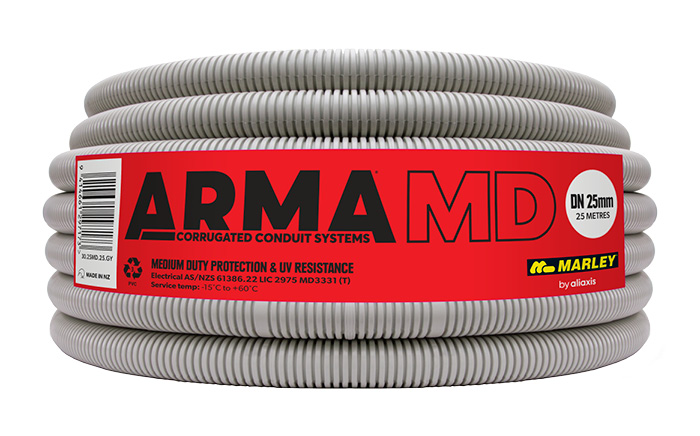

| ARMA® HD | ARMA® MD | |

|---|---|---|

| Size | ||

| Diameter (mm) | 20*, 25*, 32 | 20*, 25*, 32, 40, 50 |

| Length (m) | 25 (* = also available in 100m) | 25 (* = also available in 100m) |

| Material | ||

| Colour | Grey | Grey |

| Formulation | uPVC | uPVC |

| Temperature | ||

| Service temperature range | -15˚C to 60˚C | -15˚C to 60˚C |

| Linear co efficient of thermal expansion | 7 x 10-5 m/(mK) | 7 x 10-5 m/(mK) |

| Fittings | ||

| Marley colour match | Yes | Yes |

| Solvent Joint | Yes | Yes |

| Duty rating | Heavy Duty (4431) | Heavy Duty (4431) |

| Durability | ||

| Conduit duty rating | Heavy Duty (4431) | Medium Duty (3331) |

| Compression resistance | HD – Rating 4 | MD – Rating 3 |

| Impact resistance | HD – Rating 4 | MD – Rating 3 |

| Resistance to bending | Pliable (static only) | Pliable (static only) |

| Resistance to burning | Non flame propagating | Non Flame propagating |

| UV resistance1 | Yes2 | Yes |

| Chemical resistance | High3 | High3 |

| Compliance | ||

| Manufacturing standard | AS/NZS 61386.22 | AS/NZS 61386.22 |

| Environmental | ISO 14001 | ISO 14001 |

| Recyclable PVC | Yes | Yes |

| 3rd party verification | BV Lic. 2975 | BV Lic. 2975 |

1 Exceeds AS/NZS 61386.1 requirements

2 Meets the requirements of AS/NZS5033 – Installation & Safety Requirements for Photovoltaic (PV) Arrays

3 Avoid contact with ketones, esters, aromatic and chlorinated solvents

INSTALLATION OF CORRUGATED CONDUIT

Although it is designed for use above ground it can also be used in buried applications. Please refer to the wiring installation standard AS/NZS 3000 for guidance.

Fixing

Where conduits are to be surface mounted, secure to the building fabric with the correct size saddles or conduit clips using zinc plated or stainless steel screws into wood or masonry anchors. Galvanised or stainless steel screws may be preferred in exterior or corrosive environments while galvanized nails may be used for securing saddles in most interior applications.

Where being used in a horizontal plane it is recommend that saddles be fixed at intervals not exceeding 600mm and 1000mm in a vertical plane. Allow provision for expansion and contraction where required.

Where conduits are to be embedded in concrete the conduit should be secured from being displaced during pouring and vibrating by securing to the formwork or reinforcing.